When young Brian Adams proudly brought home a signed D.A.R.E certificate from school, Brian’s mom, Kathy, probably didn’t think much about it. Any kid that went to public school in the ‘90s brought home a D.A.R.E Certificate after a school safety officer came into our classroom and told us all about the perils of illegal drugs. A couple of decades later, Kathy sees that same certificate every day, but it’s hanging in the Nimbus Cannabis Co. headquarters

“Brian is the CEO, Andrew, the youngest is the CFO,” Kathy said. “Their brother is a marketing and data analyst and he’s helping them. He’s a sports guy, but he’s enjoying working with his brothers, so it’s nice to see.”

Brian’s grandpa (Kathy’s father) built the building when he was a young man. The original building was a manufacturing facility for ice buckets in the 1970s and it switched to electronic manufacturing in the ‘90s and remained so until the building was vacated in the 2000s.

“So Brian, very passive aggressively said, why don’t we just make it a grow?” Kathy said reminiscing with a smile and a laugh. And the rest is history, Brian founded Nimbus Cannabis in January 2018.

Six years later Nimbus Cannabis is easily producing some of the best cannabis on the East Coast if not the entire country. Their processing facility is making major moves in the repacking and processing department and they aim to help a lot of other cannabis licensees in the state process dabs and vape carts for their respective brands. For example, Cheeba Chews in Massachussetts are filled with Nimbus’s distillate.

It’s a good thing Brian ignored that bore of a D.A.R.E. officer like most of us did back in the day.

Nimbus Cannabis and the Blue Piff Strain

Nimbus’s repacking and processing operation is an important pillar of their business. Lab director Jack Sealey described it as their “bread and butter.”

The revenue it brings in allows them to subsidize special projects throughout the farm and grow strains normally not seen as commercially viable.

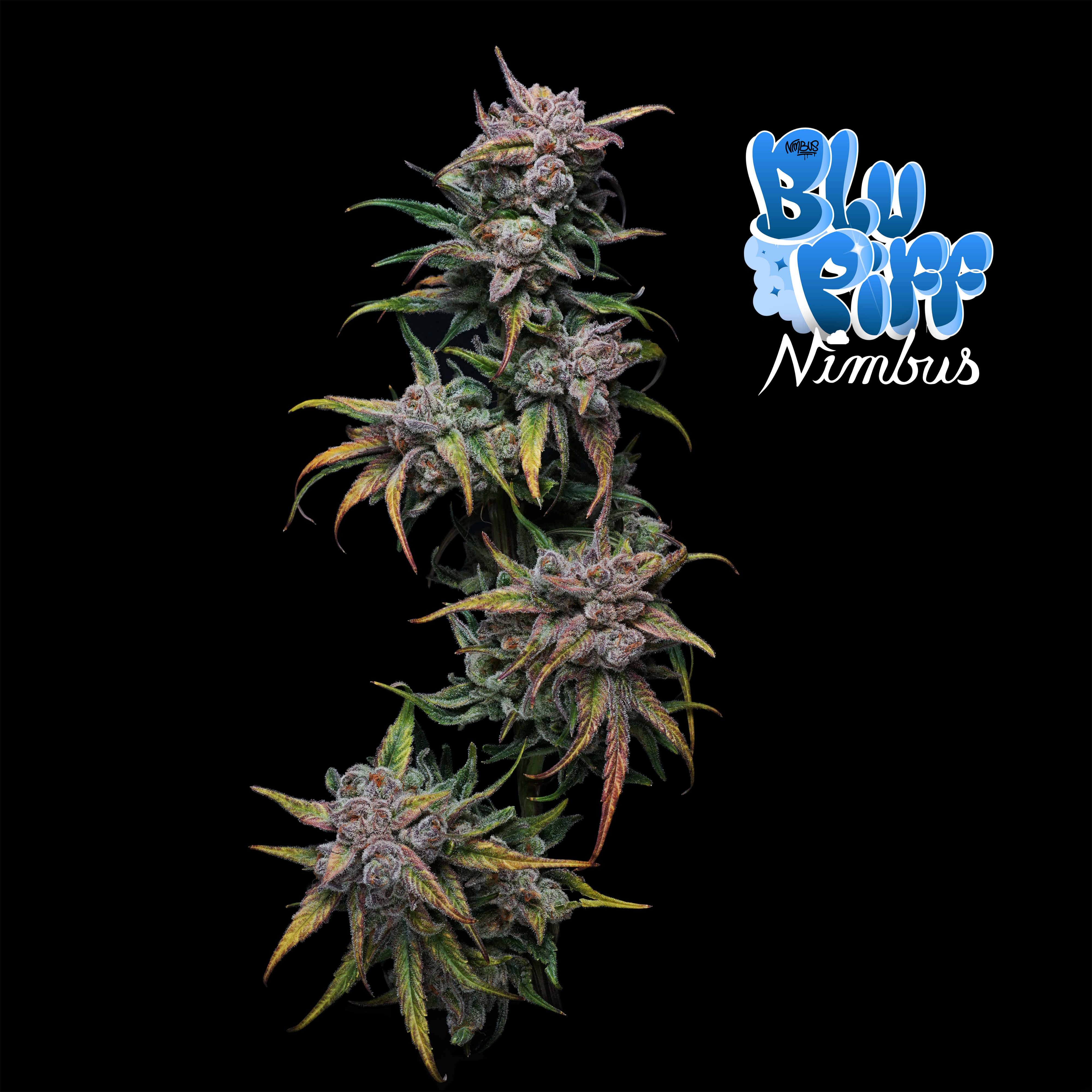

Enter the Blue Piff strain.

This NYC Piff x Blue Dream cross is a shining beacon that highlights all of the care Nimbus puts into each part of its process.

“I hit this Blue Piff live resin vape and it was so fire. It took me four tries to get my intro right for this damn interview,” Joey Brabo said in his interview with Brian on the Respect My Region podcast.

Needless to say, he can’t hit the Blue Piff before interviews anymore.

The Nimbus Cure

Creating a strain that is powerful and expressive is not easy, it takes a meticulous approach to the entire cultivation process. The drying and curing process is crucial to preserving the quality and full expression of cannabis.

Many traditional methods are outdated and not suited for commercial-scale operations.

Traditional curing methods involve maintaining specific temperature and humidity levels using basic setups like dehumidifiers, clothes hangers, mason jars, and turkey bags. And while these tools all have their place, modern operations require more advanced, science-driven approaches to improve consistency and quality.

Dew point, a measure of air moisture, was the key to dialing in the cure. Optimal curing involves balancing cooler temperatures with higher humidity to achieve consistent dew points but you can find different temperature and humidity combinations that yield the same dew point. Cannatrol’s patented storage technology allows Nimbus to dial in a dew point that allows every strain to cure the same.

Nimbus employs a 10-day curing process to bring out preferred flower characteristics. “You know, we found that we like our flower slightly on the drier side,” Brian said.

Blue Piff didn’t wash well and wasn’t commercially viable as a rosin, but as a live resin, it became one of the most flavorful and powerful concentrates on planet Earth. This is why Brian wants to “make BHO great again.”

While solventless concentrates like rosin are all the rage, Brian and Jack are on a mission to bring credibility back to live resin and other solvent-based concentrates. This means that Nimbus’s lab is a strict NO CRC zone.

Color-remediation-chromatography (CRC) is a big fancy word for ‘mids’ in the concentrate market. It’s an extraction technique that gives basic live resin better jar appeal at the cost of terpene expression and flavor.

Ocimene (also known as beta-ocimene) is all the rage right now. This terpene is common in heavy haze strains like Dutch Treat, Super Lemon Haze, Space Queen, and Strawberry Cough.

Brian said on the RMR podcast that they’ve noticed strains high in ocimene have a reddish color when you extract them. A red-cured resin isn’t something you’re going to see very often and that’s why Nimbus Cannabis likes creating it as a self-proclaimed “flavor factory.”

It’s Like a Circle

When you visit Nimbus, there are pictures from the 1940s of Kathy’s grandpa and her mom with their prized gladiolus. Kathy’s grandfather was a prize-winning horticulturist, so in a way, this new venture as a cannabis grower is cyclical as Kathy and her boys. Returning to farming and growing the best gladiolus in the world just runs in the family.

These days gladiolus looks more like an extensive vape lineup from distillate to live and cured resin, disposables, and 510 threads.

Their “flowah” lineup is headlined by none of the Blue Piff strain and a smorgasbord of other incredible strains like Boston Stranglah, Gushmints, Gastro Pop, and many more Piff crosses to come.

It might not be gladiolus or ice buckets, but the family business is thriving and Grandpa would be proud.